Build a robot arm to reach high things

Build a simple extendable robot arm using cardboard, string, and a pulley system to safely reach and retrieve lightweight high objects.

Step-by-step guide to build a robot arm to reach high things

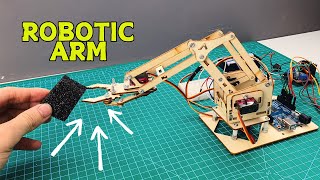

Popsicle Stick Robotic Arm with Arduino | Science Project

Step 1

Gather all your materials and clear a flat workspace so you have room to build.

Step 2

Measure and mark three cardboard strips: one long about 50 cm one medium about 35 cm and one short about 20 cm.

Step 3

Cut the three marked cardboard pieces out carefully with scissors or a craft knife while an adult helps.

Step 4

Fold up 1.5 cm sides along both long edges of each strip to make U-shaped sliding channels.

Step 5

Slide the short strip into the medium strip and then slide those into the long strip so they nest and can slide telescopically.

Step 6

Lay a pencil across the top of the long outer channel near its far end and tape each pencil end so the pencil can roll freely as a simple pulley.

Step 7

Feed one end of a length of string into the open base of the long channel and push it through the nested sections until the string comes out over the pencil at the tip.

Step 8

Tie a paperclip hook onto the string that is sticking out at the tip and tape the knot to the short inner section so the hook sits outside the arm.

Step 9

Bring the long free end of the string back over the pencil pulley and to the base and tie it to a clothespin or wrap it around a second pencil to make a small winch.

Step 10

Secure the base of the long channel to a table edge with tape or hold it firmly so the arm stays steady while you operate it.

Step 11

Turn the winch pencil or pull the free string slowly to extend the inner sections and watch the arm reach out.

Step 12

If the sections stick or rub add small pieces of tape to smooth edges or loosen the folds so the parts slide easily.

Step 13

Use the paperclip hook or clothespin to gently hook a lightweight high object and lift it down slowly and safely.

Step 14

Put away sharp tools and tidy your workspace when you finish so everything is safe and ready for next time.

Step 15

Take a photo or make a short note about your extendable robot arm and share your finished creation on DIY.org

Final steps

You're almost there! Complete all the steps, bring your creation to life, post it, and conquer the challenge!

Help!?

What can we use if we don't have pencils, paperclips, or a clothespin?

Use wooden dowels, chopsticks, or tightly rolled cardboard tubes for the pulley and winch (Steps 7 and 9), a bent wire loop or straightened coat hanger instead of a paperclip for the hook (Step 8), and a binder clip or small spool in place of a clothespin for the winch attachment (Step 9).

Why won't the cardboard sections slide smoothly and how can we fix it?

If the nested strips stick when telescoping (Step 5), smooth rough cut edges with small pieces of tape, gently loosen the 1.5 cm folded tabs (Steps 4 and 11), or trim/sand any uneven cuts so the U-shaped channels glide freely.

How should we change the activity for younger kids or for older kids who want more challenge?

For younger children have an adult pre-cut and fold the cardboard and set up the taped pulley and hook (Steps 2–8), while older kids can reinforce the channels with thin skewers or glue-on strips and upgrade to fishing line and a two-pulley winch for extra reach and load (Steps 4,7,9).

What are simple ways to enhance or personalize the robot arm after it's built?

Decorate the cardboard, replace the paperclip hook with a small hinged cardboard claw attached to the short inner section (Step 8), and mount the long channel base to a piece of stiff cardboard or clamp it to the table (Step 10) for improved stability and grip.

Watch videos on how to build a robot arm to reach high things

Simple Homemade Robotic Arm! | Argo's World | STEM for Kids

Facts about simple machines and basic engineering for kids

🪢 A bowline knot makes a secure, easy-to-tie loop that rescue teams and sailors love because it usually won’t slip.

📦 Corrugated cardboard is strong for its weight because a wavy (corrugated) layer between flat liners acts like tiny beams.

🪜 Engineers add triangular bracing to long arms and cranes to stop wobble — triangles keep structures rigid.

🤖 The first industrial robot, Unimate, started working on a General Motors assembly line in 1961.

🧰 Using multiple pulleys (a block and tackle) can multiply your lifting power — each supporting rope segment shares the load.

How do I build a simple extendable robot arm to reach high things?

What materials and tools do I need to build a cardboard robot arm?

What ages is this extendable robot arm activity suitable for?

What safety tips should parents follow when kids build and use the robot arm?

Make things. Learn new skills. Share safely.

DIY is a creative community where kids draw, build, explore ideas, and share.

No credit card required